Hydroponic Strawberry Irrigation

Irrigation (fertigation) is a key management technique in high quality strawberry production. However, there is much room to optimize the nutrient solution and its application. The following is information based on our study at the University of Arizona and may not be directly applicable to your conditions.

Nutrient recipe. There is limited information available for hydroponic nutrient solution designed for strawberry. We have used a Japanese hydroponic strawberry solution and the concentrations of major ions are shown in the following table. Compared to those solutions widely used for tomato and other greenhouse crops (EC = ~2.4 dS/m at the full strength), the Yamazaki strawberry solution has much lower overall concentration (EC = ~1.0 dS/m at the full strength). Adding a small percent of nitrogen in NH4 form helps to minimize the increase of pH in the root zone. However, too high NH4 rate should be avoided as plants become too vegetative.

Table. Major elemental concentrations (mg/L or ppm)

pH (5.5-6.0). The nutrient solution pH should be in the range (5.5 – 6.0). When root zone (or drainage solution) pH exceeds 7.0, young leaves turn yellow-green, a typical symptom of iron deficiency, which restricts overall growth of plants.

Actively growing roots in hydroponics take up hydrogen ion (H+) together with NO3-N uptake. This increases root-zone pH, to become more basic. However, when roots are old and not functioning, we see pH go down mainly due to oxidation and deterioration of roots.

EC (1.0 dS/m or less). EC is electrical conductivity and is an indicator of the total concentration of ions dissolved in the solution. Many experts of greenhouse hydroponic strawberry suggest that strawberries are sensitive to salts accumulated in the root zone. When the root-zone EC exceeds 1.2 dS/m, the growers often flush the root-zone with water to wash off the excessively accumulated salts in the root zone. However, this practice is suggested by Japanese hydroponics consultant and is something about which we have not yet reached a conclusion out of the study at the University of Arizona as higher EC levels may be acceptable (depending on cultivars).

Irrigation management in substrate-based system. A typical irrigation set up consists of concentrated fertilizer injectors, drip irrigation system with pressure compensated emitters, and lysimeter set-up to measure EC, pH, and volume of drip and drain nutrient solution. Strawberry plants are sensitive to ‘too wet’ or ‘too dry’ conditions. For substrate-based production, we will need more research to find the optimum range of moisture content in the root zone. In order to avoid large fluctuation of the moisture content, we irrigate frequently with a very small amount (33 mL per plant at a time), rather than only one or two large irrigation events per day. The total irrigation applications per day depends on the total ET (evapotranspiration rate) as affected by the greenhouse environments (solar radiation, temperature, and VPD) as well as the plant leaf area index, but it has been between 6 to 12 irrigation events per day (~200 mL to ~400 mL per plant per day) over last few years.

Drainage percent (30-40%). Assuring a good drainage percent is a standard key practice in root zone management for hydroponics. The recommended drainage percentage for strawberry is 30-40%, a similar level to tomato and other crops. We also try to not have any drainage in the early part of the day. Having a measurable amount of drainage at the first few irrigations of the day is an indication that the root zone is too wet.

Nutrient delivery system (various hydroponics). Strawberry hydroponic systems used commercially are either a substrate-based aggregate hydroponics (described above and in ‘substrate’ page) or a nutrient film technique (NFT). Both systems allow the workers to stand while they work on plant management tasks. For substrate based system, various trough systems are commercially available in Asia, Europe and Israel, where strawberries are intensively cultivated hydroponically. But only limited options are available in the US. Strawberry NFT has been practiced commercially but to a lesser extent than substrate-based hydroponics. The reason NFT is used less may be associated with the long production cycle of strawberry and that NFT is a risky system with little buffering capacity upon any system failures.

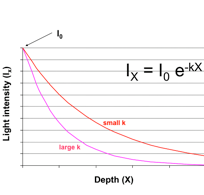

Other systems that are used commercially are 1) aeroponic system in which roots are hanging in the air with frequent spraying of nutrient solution, 2) bucket system to be assembled into a trough, which is a compartmentalized version of trough system with substrates, and 3) vertical stacking bucket system with nutrient solution trickling down from the top container to the bottom. The last system, although it is visually attractive, is more challenging to obtain uniform growth and fruit yield for strawberry, as the light reaching the “plant canopy” exponentially decreases with increasing depth from the top of the canopy. At a high density, the plants in the lower buckets may not receive enough light to have positive carbon balance during most of the daytime, while top of the canopy receives over-saturating light intensity. Therefore, when such a system is introduced, careful considerations are needed for the greenhouse light environment (the incident light to the canopy) and the density (number of vertical systems per growing area). The differences in light intensity and the resulting strawberry fruit yield between upper and lower layers of vertical growing system was reported by Takeda (1999).

Updated (8/15/14)

Drip irrigation system in a Styrofoam trough system (one emitter per plant). Picture was taken before mulching.

Drip irrigation system for a bucket system. Picture was taken before mulching.

Drip irrigation line and emitters are under the white mulch (Styrofoam trough system).

Light intensity inside plant canopy (Ix) declines exponentially with being deeper in the canopy. The k value is called extinction coefficient, and is affected by canopy structure, plant density, and amount of leaves (LAI).

‘Arizona Gutter System for Greenhouse Strawberry Production’, ‘Arizona Greenhouse Strawberry Bucket System’ and ‘Arizona Fertilizer A and B Stock Formulations’ videos produced by Dr. Mike Evans at University of Arkansas. University of Arizona collaborates with Dr. Mike Evans for developing series of educational videos to learn hydroponic strawberry production. Visit the Hydroponic Strawberry YouTube Channel.

This project is funded by a grant from the Walmart Foundation and administered by the University of Arkansas System Division of Agriculture Center for Agricultural and Rural Sustainability. Any products, services or organizations that are mentioned, shown or indirectly implied in this website do not imply endorsement by the University of Arizona.