|

Onsite Wastewater System Compliance

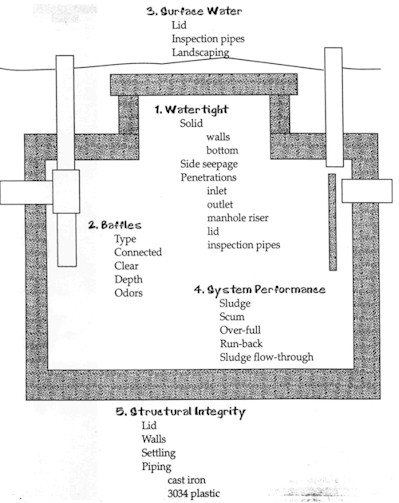

Inspections: Septic Tank Evaluation

Inspection will often take place at the time of a property transfer and the use of the system by a new owner. The inspection consists of three pieces: the current use of the system and the effects of the use, the condition and performance of the septic tank, and the condition and performance of the soil treatment system. The order in which you inspect the parts of the onsite system may be dictated by the site, but a typical order of completion is to analyze the system use, then the septic tank, and then the soil treatment system. You are not required to address all the defects of the system, but a thorough inspection can be useful in the decision-making process. This module will cover the condition and performance of the septic tank and may take up to 58 seconds to load.. Please note that this information was adapted from National Association of Wastewater Transporters, Inc. Inspection of Existing Onsite Treatment Systems. St. Paul, MN.

The septic tank holds a wealth of information about the operation and performance of the whole onsite system. Some states use the tank as the single point of information about an entire system. Although your inspection will include examinations of other system components, start by opening the tank and looking into it. For many tanks, that means opening the 20-inch manhole. For other tanks, it means taking a section of the lid off. You have to be able to see the inside of the tank, so opening the four-inch inspection pipe will not be sufficient. Finding the tank can be difficult. Water flows downhill, so usually the tank is downhill from the house. The sewer service coming out of the house will give you a general direction, and then look for clues: an inspection pipe, a low spot, dead grass, early snow melt, or other landscaping.

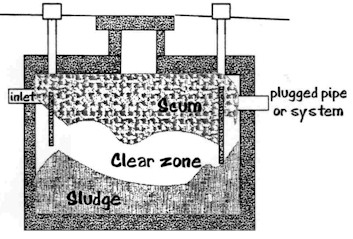

Flow, Settling, and Bacterial Action First, get a general overview of the tank and its contents. If there's a lot of floating material that doesn't belong in there, such as plastic products or undigested food, you know that the users of the system may be causing some problems.

Evaluate the scum layer. It should be excessively thick and should always be less than three inches from the bottom of the outlet baffle to ensure that the scum is not leaving the tank. The scum layer should also not be higher than the outlet baffle.

Excessive scum in the tank may mean that the tank needs to be cleaned out, or it may mean that the wastewater has high levels of soap or grease. Users of the system may be able to reduce the amount of soap or grease in the water, or they may have to have the tank pumped out on a more frequent basis. For systems serving commercial establishments, such as restaurants, it may be a good idea to extend the outlet baffles, so that the first of two or three tanks becomes a grease trap. Another component of scum is undigested food. If a particularly thick scum layer contains a large proportion of undigested food, there is usually a problem in the house, either excessive garbage disposal use or a medical problem such as bulimia. The users of the system should deal with these issues. Other materials to check for include feminine hygiene products, such as tampons, and pads, and barrier-method birth control products, such as condoms. These products should not be in the septic tank! They will neither sink nor float; instead, they will tend to flow through the septic tank and into the soil system, where they can plug both the outlet line and the soil system. Users of the system should understand that these products must not become part of the sewage flow. For systems serving restaurants or other commercial establishments, an effluent filter to prevent these materials from leaving the tank may be necessary.

If there is an excess of material that cannot be broken down by the bacteria in the tank, such as coffee grounds, soil, or soap, both the scum and the sludge layers can quickly become too thick. The only way to get these materials out of the tank is by pumping.

If a lift station is part of the system, the pumps may have had problems, causing the tank to overfill. If, after pumping out the tank, there is excessive runback (water entering the tank from the outlet side) into the tank, there is likely plugging of the soil treatment area.

Check the performance of the system by testing the quality of the effluent. The septic tank should be producing effluent with a biological oxygen demand (BOD) of less than 175 mg/L, total suspended solids (TSS) less than 60 mg/L, and fats, oils, and grease (FOG) less than 30 mg/L. When the effluent has higher values than these, the soil treatment portions of septic systems typically develop problems.

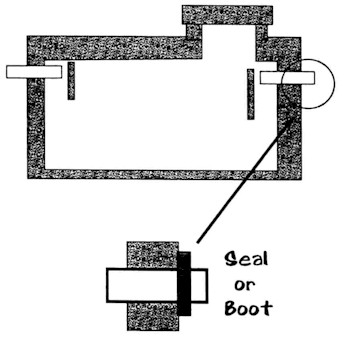

The key to accepting the tank is the watertightness of the tank. If it is watertight, then it meets the minimum requirement. Watertight means that water is not allowed to flow in or out of the tank other than through the design penetrations (inlet and outlet pipes). Watertightness is critical to septic tank performance. Excess water entering the tank from surface runoff can result in inadequately-treated effluent entering the soil treatment system, causing premature failure of the soil system. Untreated wastewater entering the soil from a leaky septic tank presents health risks to humans and can have grave environmental consequences. The licensed pumper can help determine if the tank is watertight and may be a useful resource about the system. General experience has been that most tanks without maintenance access are not watertight. Verify that the concrete walls are watertight. Pay particular attention to seams in the walls. Tanks with mid-wall seams have a high probability of not being watertight. These walls should include some type of tongue-and-groove; check this joint. Inspection of the walls includes checking the corners where the cover and the walls meet. These joints also should have a tongue-and-groove connection and some type of a mastic sealer on them. The other watertight surface is the tank bottom. This may seem pretty straightforward, but many tank floors were not properly constructed and are not watertight. Next, check all the penetrations, including inlet, outlet, manhole riser, manhole lid, and inspection pipes. All of these should be watertight. A very good hint that they are not is the intrusion of roots. Presence of roots indicates a problem that has been in existence for a long time. Another indication of a problem is a trickle of water entering the tank. Surface water must not be allowed to enter the system. One place it might is through the manhole, which can be buried to minimize some of the surface. If it is not buried, it should be elevated at least one inch above the finished grade to guarantee that you do not have excessive flow into the tank. Sealing this lid may seem like a good option, but sometimes a sealed manhole lid becomes permanently sealed and cannot be opened for maintenance. A number of local authorities require that the maintenance access be brought to the surface. This is a good idea, but if access is not brought to the surface, the system can still be in compliance. Inspection pipes must be watertight at the surface of the tank. More importantly, they must have a cover on them. A coffee can is not a cover. The cover should be a tight-fitting plastic pipe. The best cover would be a threaded cap, to allow repeated opening without affecting the fit of the cover.

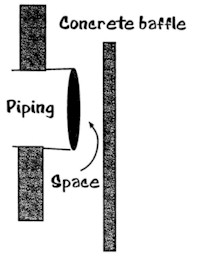

With large-diameter smooth-wall plastic pipe, it is critical that a seal be made where the pipe is connected to the tank. Simply setting the pipe on top of the tank does not make a watertight connection. Another consideration is the location of the septic tank in the landscape. It should be located where a particularly aware of hard surfaces, from which the most water will run off; ideally, the tank would be upslope from these.

Check the baffles in the tank. The baffles begin the settling process by forcing the flow down, keeping the scum inside the tank, and ensuring that effluent leaving the tank comes from the clear liquid layer. If there are problems with the baffles, the system cannot work properly. There are two general types of baffles: plastic pipe (sanitary tees) and wall baffles. The advantage of the wall baffles is that they are built in. They have a larger space to allow the falling through or moving through of bigger chunks. The downside of the wall baffles is that if the tank is not properly constructed, the baffles will be significantly impaired. It's also difficult to add effluent filters to a tank with wall baffles. But either type of baffle will work adequately as long as it's in place. Baffles must be properly connected. If it is a wall baffle or a large pipe

baffle, it should be connected in a way that it will not corrode. All baffles

must be securely attached, so they remain in place over the life of the tank,

and they must be inspected. Baffles made of PVC sanitary tees must be properly

glued and affixed onto the system.

During the inspection you also want to verify that the baffles are clear (that nothing is plugging them). It's a good idea to verify that there is enough free space between the inlet pipe and the baffle to allow the free flow of both water and the solids in the water. There should be two to four inches between pipe and baffle. Note the depths of the baffles: the inlet baffle should be at least six inches deep. The outlet baffle should be drawing from the clear portion of the septic tank, typically about 40% of the depth. If the tank's function is to contain excessive suds or grease, the depth of the outlet baffle may be lowered so that the tank functions as a grease trap.

Tank Construction and Installation Check the structural integrity of the tank. The lid should be strong enough to support the weight of a man (say 200 lbs.). If the lid is at the soil surface, strength is critical. Some concrete tank lids have two different thicknesses to hold them in place, which is a good idea, but if the top lid is too thin there can be problems. Walls must be strong enough to maintain seven feet of saturated soil overburden. Refer back to the original design of the tank. If the tank is deeper than seven feet, there should be special design considerations so that its performance will be adequate in those conditions. Check for settling of soil around the tank. Depressions in the soil at the edges of the tank can lead to ponding of rainwater, followed by infiltration. The outlet pipe should also be constructed and installed to minimize soil settling. Note the presence of cast iron pipe, which can react with soap products, causing corrosion and eventual plugging. Cast iron pipe should be avoided or replaced if at all possible.

Is there any odor in the vicinity of the septic tank? Odors typically indicate a venting problem. Odors should be vented out through the system, not back through the house.

After the system use has been researched and findings noted and the septic tank has been inspected, it's time to inspect the soil treatment system.

Material last reviewed: April 22, 2002 © 2000 The University of Arizona. All contents copyrighted. All rights reserved. |

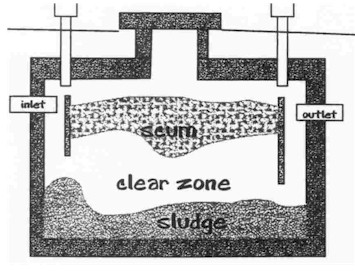

The tank should be developing three separate layers: a scum layer

on top, clear water in the middle, and a sludge layer on the bottom. If these

three separate layers are not present, then the system is not operating the

way it should, and you need to find out why. When wastewater doesn't form these

layers, it's often because some type of chemical has been added that has killed

the bacteria or because one of the baffles in the tank is missing. Sometimes

the layers will form but then become mixed due to turbulence in the water, in

particular if there is a pump in the basement introducing too much water into

the system.

The tank should be developing three separate layers: a scum layer

on top, clear water in the middle, and a sludge layer on the bottom. If these

three separate layers are not present, then the system is not operating the

way it should, and you need to find out why. When wastewater doesn't form these

layers, it's often because some type of chemical has been added that has killed

the bacteria or because one of the baffles in the tank is missing. Sometimes

the layers will form but then become mixed due to turbulence in the water, in

particular if there is a pump in the basement introducing too much water into

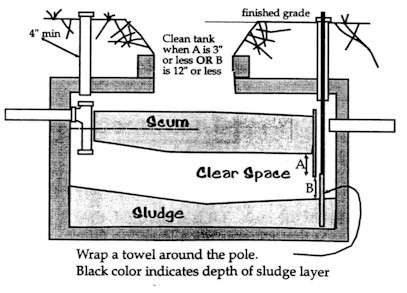

the system. Evaluate the sludge layer. It should not be within 12 inches

of the bottom of the outlet. Allow time for the sludge to settle before measuring

this distance. Verify that the sludge is settling well and that there is not

excessive movement of sludge out of the tank. Sludge will not settle properly

if the water in the tank is turbulent. Turbulent conditions could be from a

pump in the basement adding high volumes of water, "stirring up" the

wastewater. Or there may simply be too much water entering the tank. If sewage

flow from the house to the tank has increased since the tank was designed and

constructed, the tank may not be large enough to handle the amount of wastewater

entering it. Users of the system may be able to reduce their water use to improve

the performance of the system.

Evaluate the sludge layer. It should not be within 12 inches

of the bottom of the outlet. Allow time for the sludge to settle before measuring

this distance. Verify that the sludge is settling well and that there is not

excessive movement of sludge out of the tank. Sludge will not settle properly

if the water in the tank is turbulent. Turbulent conditions could be from a

pump in the basement adding high volumes of water, "stirring up" the

wastewater. Or there may simply be too much water entering the tank. If sewage

flow from the house to the tank has increased since the tank was designed and

constructed, the tank may not be large enough to handle the amount of wastewater

entering it. Users of the system may be able to reduce their water use to improve

the performance of the system. If

the septic tank is over-full (if the water level is higher than the outlet invert),

the system is not operating as it should. An over-full tank is not conducive

to settling, so sludge and other solids may reach the soil treatment area. There

may be plugging in the line, or the soil treatment system at the other end of

the line may be plugged.

If

the septic tank is over-full (if the water level is higher than the outlet invert),

the system is not operating as it should. An over-full tank is not conducive

to settling, so sludge and other solids may reach the soil treatment area. There

may be plugging in the line, or the soil treatment system at the other end of

the line may be plugged. There

should be self-sealing gaskets wherever penetrations meet the tank walls or

lid. A number of the newer septic tanks have gaskets that require some type

of a masonry support to work. The riser itself needs to be watertight at all

joints; plastic and concrete materials are available to achieve this. The typical

length of the riser is 10 to 12 inches, so using concrete means more pieces

are necessary to bring it to the surface, and every connection must be watertight.

There

should be self-sealing gaskets wherever penetrations meet the tank walls or

lid. A number of the newer septic tanks have gaskets that require some type

of a masonry support to work. The riser itself needs to be watertight at all

joints; plastic and concrete materials are available to achieve this. The typical

length of the riser is 10 to 12 inches, so using concrete means more pieces

are necessary to bring it to the surface, and every connection must be watertight.